Kinetic Installations

↑

WHY KINETIC INSTALLATIONS?

We believe in the power of physical movement. It allows content to emerge vividly and create literally outstanding effects.

What exactly are KINETIC INSTALLATIONS?

Kinetic installations consist of a large number of moving components. Their dynamic effects vitalise visitor experiences and media facades alike.

HOW DO WE DEVELOP KINETIC INSTALLATIONS?

To develop kinetic installations, we design, build, programme and configure.

We have realised kinetic installations

for a wide range of contexts:

Musée Internationale de la Réforme

Kinetic Window Installation

- 100 dichoic glass discs rotate on 8 axes

- Noiseless operation with stepper motor

- Security mechanism for safe museum operation

- Maintenance-free plastic bearings

- Light from a projector is mapped onto glass panes

- Artificial light and daylight combination

Endress+Hauser «Flow Experience»

Kinetic Wall Indoors

- 160 motors driving movable cubes over a width of 15 metres

- 32 cm maximum extension into the room

- 5 seconds for complete, dynamic expansion

- Control via media tables in the room and ultrasonic sensors

- Quiet and low-maintenance operation thanks to stepper motors, plastic plain bearings and toothed belts

- Real-time frame-accurate synchronisation of the cubes' position and projected contents

Peter Jones Flagship Store

Facade With Kinetic Blade Displays

- 133 panels with horizontal blades

- By day: blade rotation leads to shift between light and dark

- By night: blade rotation leads to transparency towards LED rear light

- Facade reacts to current weather data by changing contrast, speed and colour, shows a new mosaic every day

Schindler CityScape

Vertical Kinetic Installation Indoors

- Cross-screen content on 29 moving screens

- Screens are moved up and down depending on content

- Drive by servo drives with PLC

- Synchronisation of screen positions via serial protocol

- ‘Digital Twin’: Virtual 1:1 model for configuration and content design in real time

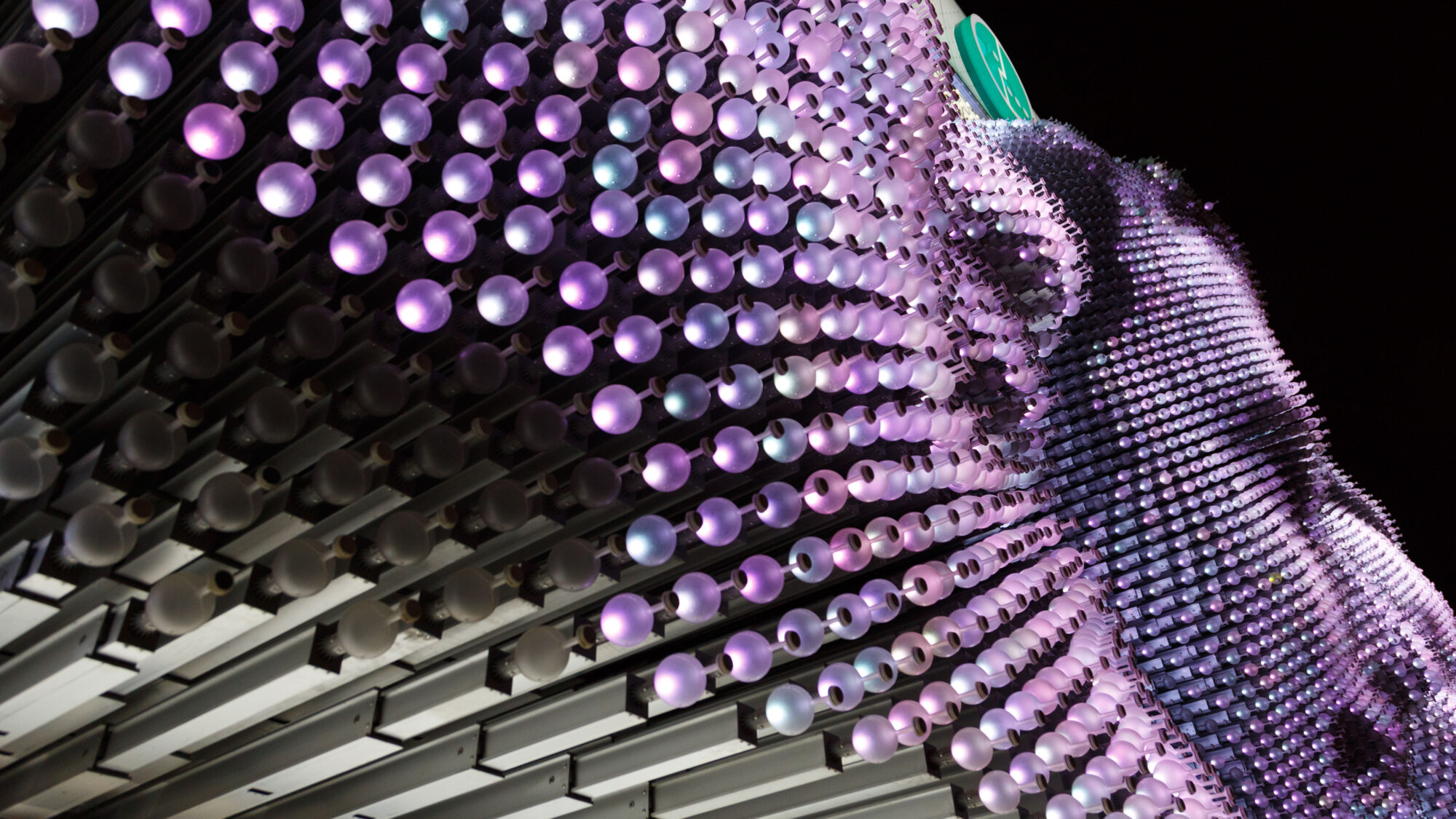

Sotchi MegaFaces

Monumental Kinetic Exterior Facade

- 11,000 individually controllable and extendable actuators on a facade area of approx. 15x30 metres

- 2-stage telescopic cob actuators (in-house development)

- 2 metres maximum extension

- Driven by DC motors with worm gears

- Incremental position sensor and cable pull system for return

- High-performance LED at the top of each actuator

- Content preview using real-time 3D visualisations

Do you have a question, an idea or a project?

We’d love to hear from you – whether it’s just to connect or to discuss a potential collaboration.

→ Contact us